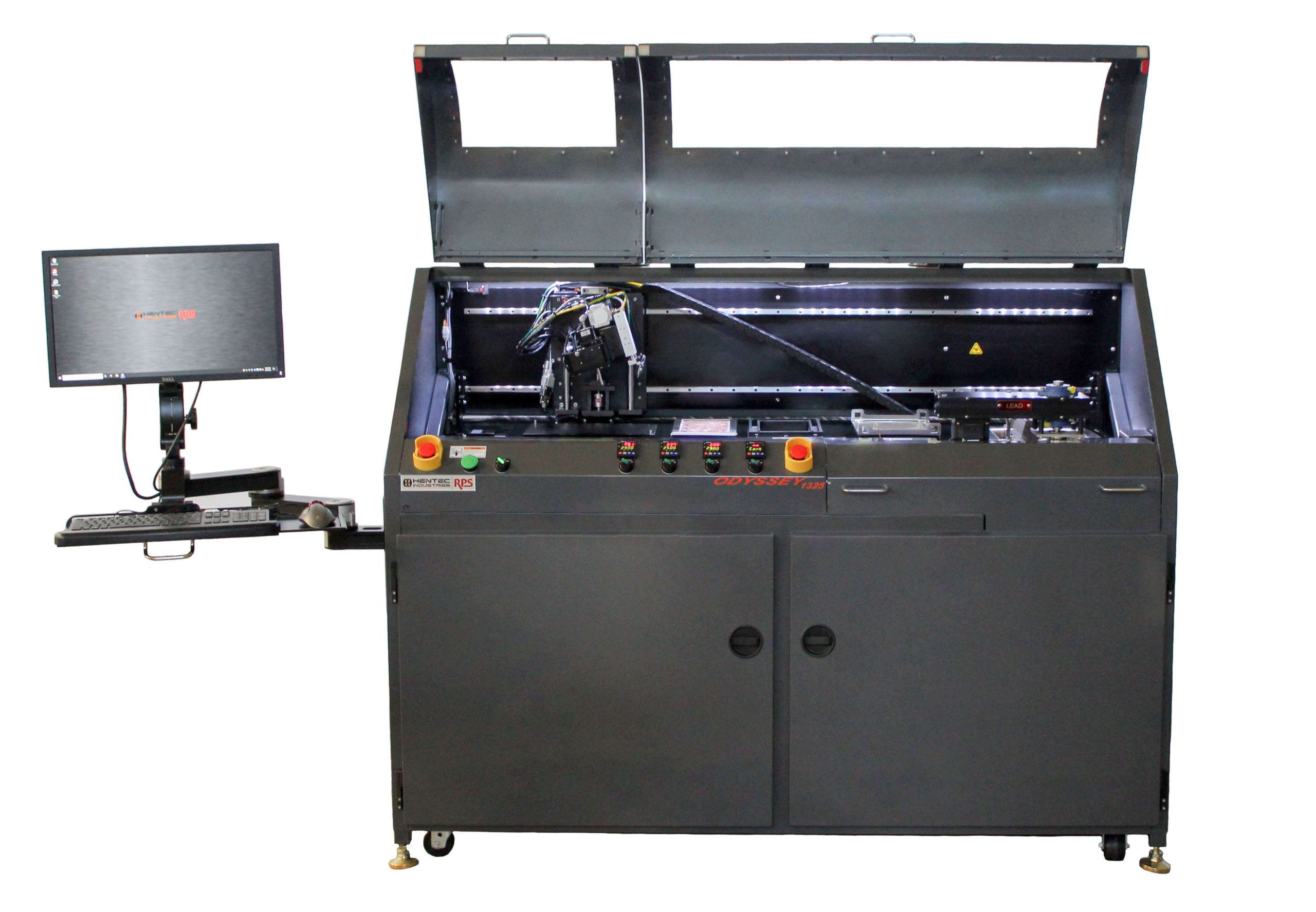

CiRCLE Engineers Purchases Hentec/RPS 1325 Odyssey Lead Tinning System for Israel Facility

Odyssey 1325 provides high reliability BGA alloy exchange and component re-finishing capabilities

Newman Lake, WA (October 19, 2021) – Hentec Industries/RPS Automation is pleased to announce that CiRCLE Engineers Ltd. has purchased a Hentec/RPS Odyssey 1325 robotic hot solder dip component lead tinning machine. The Odyssey 1325 is a MIL spec complaint high-volume, high-mix component lead tinning machine equipped with auto load/unload functionality and is capable of processing dual solder alloys. Designed to tin component leads for re-conditioning, gold removal and re-tinning applications, including high reliability and military applications including DIP, SIP, QFP, BGA, axial and radial components as well as BGA de-balling. The Odyssey 1325 complies with all applicable GEIA-STD-006, MIL-PRF-38535, MIL-PRF-38524E and ANSI-J-STD-002 standards.

About CiRCLE Engineers

Headquartered in Tel Aviv, Israel, CiRCLE Engineers, Ltd. manufactures high technology products for the aerospace, architecture, biology, biomedical, biotechnology, environmental, and computer science markets. Their products are used in a variety of mission critical applications including aerospace, medical and life science applications.

About Hentec Industries

Hentec Industries/RPS Automation is a manufacturer of automated selective soldering, component lead tinning, and solderability test equipment for electronics and electronic component manufacturing, assembly, and distribution. Hentec/RPS has been advancing automated soldering and lead finishing technology for defense, aerospace, automotive, contract manufacturers and micro-electronics component manufacturers since the early 90’s.

All Hentec/RPS products are designed and manufactured in Newman Lake, Washington. For more information, please visit www.rpsautomation.com.

###

If you would like more information on system sales, please contact Tom Baro at 509-385-1228 or tbaro@rpsautomation.com.