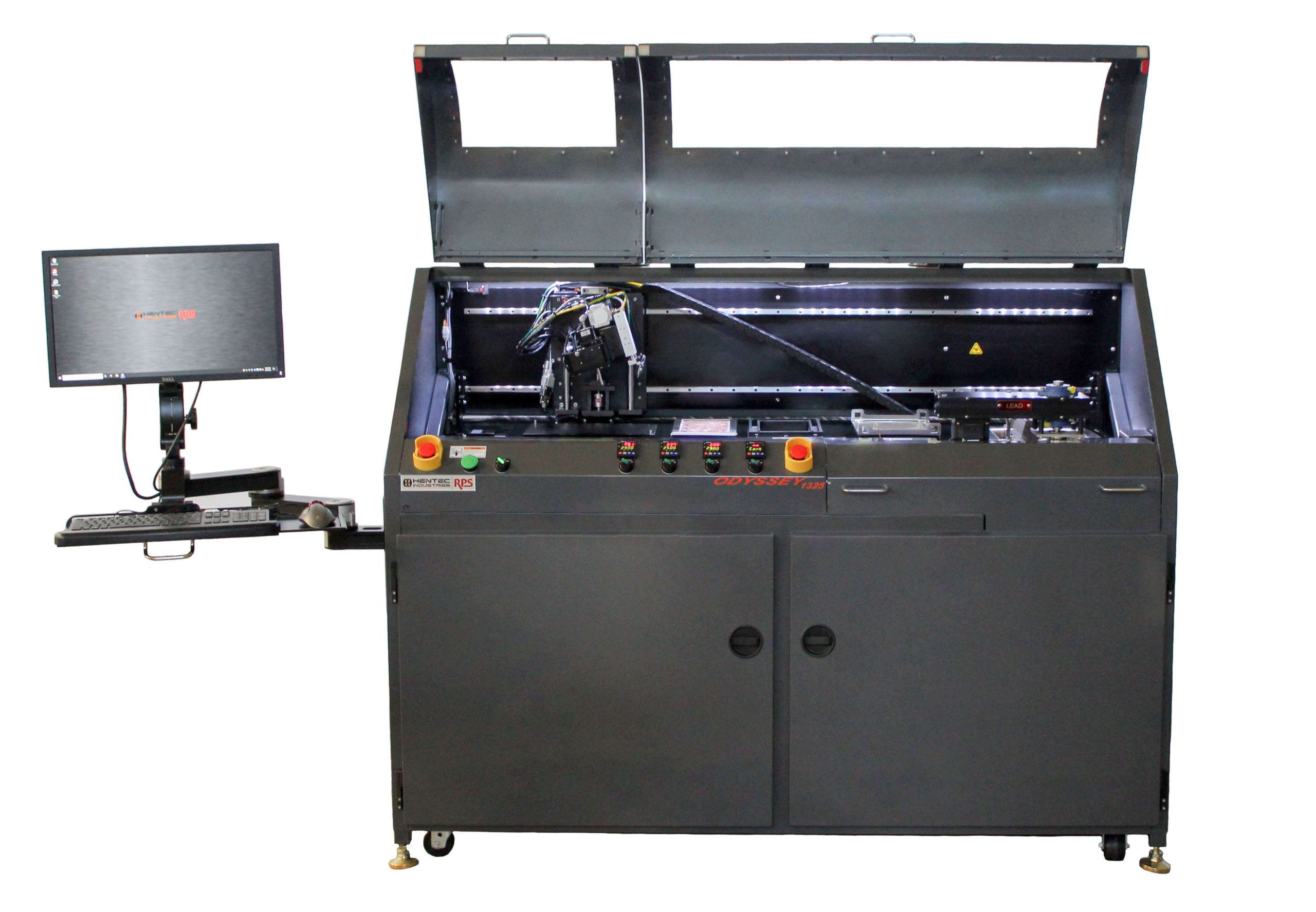

CIRCOR Aerospace Purchases Hentec/RPS 1325 Odyssey Lead Tinning System

Odyssey 1325 provides high reliability BGA alloy exchange and component re-finishing capabilities.

Newman Lake, WA – Hentec Industries/RPS Automation is pleased to announce that CIRCOR Aerospace has purchased a Hentec/RPS Odyssey 1325 robotic hot solder dip component lead tinning machine. The Odyssey 1325 is a MIL spec complaint high-volume, high-mix component lead tinning machine equipped with auto load/unload functionality and is capable of processing dual solder alloys. Designed to tin component leads for re-conditioning, gold removal and re-tinning applications, including high reliability and military applications including DIP, SIP, QFP, BGA, axial and radial components as well as BGA de-balling. The Odyssey 1325 complies with all applicable GEIA-STD-006, MIL-PRF-38535, MIL-PRF-38524E and ANSI-J-STD-002 standards.

About CIRCOR Aerospace

Headquartered in Corona, California, CIRCOR Aerospace, Inc. manufactures fluidic control, undercarriage components and subsystems for the military aerospace market. Their products are used in a variety of mission critical applications including land gear, weapon release and survival solutions. For more information, please visit: www.circoraerospace.com.

About Hentec Industries

Hentec Industries/RPS Automation is a manufacturer of automated selective soldering, component lead tinning, and solderability test equipment for electronics and electronic component manufacturing, assembly, and distribution. Hentec/RPS has been advancing automated soldering and lead finishing technology for defense, aerospace, automotive, contract manufacturers and micro-electronics component manufacturers since the early 90’s.

All Hentec/RPS products are designed and manufactured in Newman Lake, Washington. For more information, please visit www.rpsautomation.com.

###

If you would like more information on system sales, please contact Tom Baro at 509-385-1228 or tbaro@rpsautomation.com.