Hentec/RPS Publishes Achieving Greater Through-Hole Soldering Reliability Tech Paper

OEM and EMS companies need to adapt automated selective soldering processes to improve the consistency and quality of their electronic products.

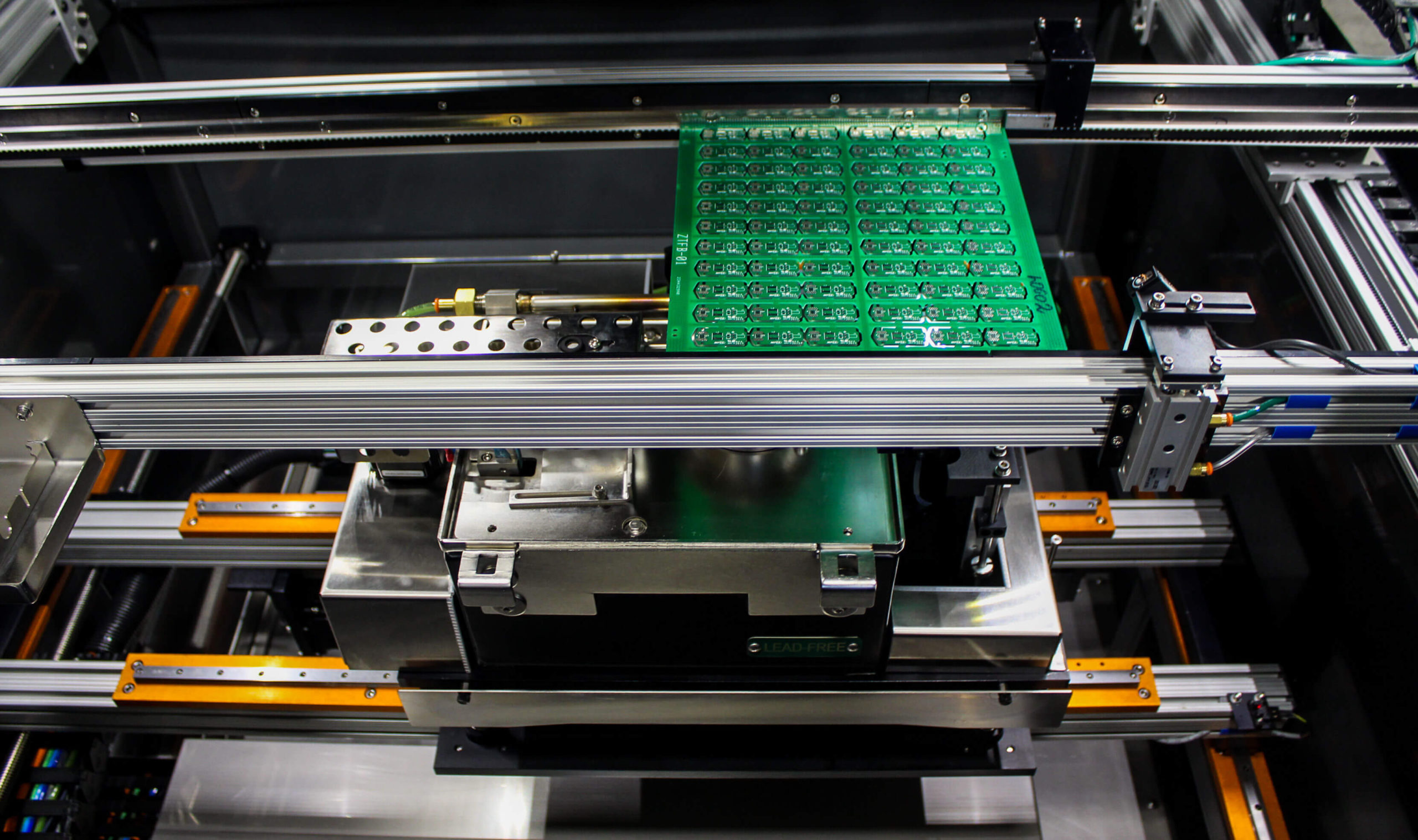

Newman Lake, WA (March 28th, 2023) – Hentec Industries/RPS Automation, a leading manufacturer of selective soldering, lead tinning and solderability test equipment, announces that it has published a technical paper describing the suggestion that electronic manufacturers should implement automated selective soldering as opposed to using manual soldering. This technical paper encompasses critically important information and is entitled “Achieving Greater Through-Hole Soldering Reliability Without Sacrificing Throughput.” This 5-page tech paper outlines essential information for circuit board assembly processes and can be downloaded by visiting www.rpsautomation.com/news/technical-papers.

Topics covered within this publication include soldering methods, manual soldering, hand soldering reliability, process considerations, versatility vs. throughput, fluxing control, process repeatability, and selective soldering system flexibility.

About Hentec Industries

Hentec Industries/RPS Automation is a manufacturer of automated selective soldering, component lead tinning, and solderability test equipment for electronics and electronic component manufacturing, assembly, and distribution. Hentec/RPS has been advancing automated soldering and lead finishing technology for defense, aerospace, automotive, contract manufacturers and micro-electronics component manufacturers since the early 90’s. All Hentec/RPS products are designed and manufactured in Newman Lake, Washington. For more information, please visit us at www.rpsautomation.com.

###

If you would like more information on system sales, please contact Tom Baro at 509-385-1228 or tbaro@rpsautomation.com.